With the cost and capabilities of industrial automation solutions continuing to improve, more and more companies are turning to automation to keep their factories competitive. Historically, robotics and automation projects were both costly to implement and complex to maintain. More recently, with the improvement of existing industrial robots and the introduction of new offerings, such as Universal Robots’ Collaborative Robots and high-speed SCARA robots from Denso, the number of viable applications continues to grow.

One of the most common questions we get asked here at Markone Control Systems, as an automation integrator, is whether a specific process is a good fit for industrial automation. There are three factors that typically come into consideration when trying to evaluate this question for any given process:

- Variability: The lower the variability a process has the better of a fit it is for automation, as sources of potential errors are reduced. Automotive has traditionally been a great example of this, where the same part is repeatedly produced hundreds and thousands of times per year. On the other side of the spectrum, if each of your products is not only customized by order but varies greatly in aspects such as size and shape, automating the said process may prove to be a challenge. However, machine vision systems becoming more adaptable than ever—this barrier is quickly fading.

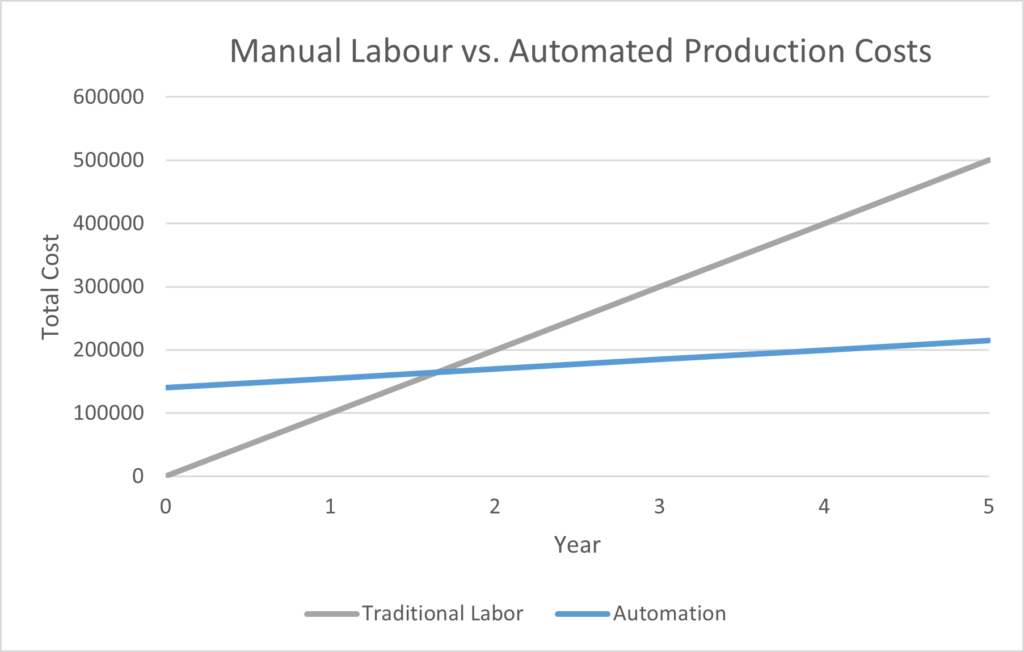

- Volume: The number of units that a given process produces in a year is the second factor that is usually a large determinant as to whether automation would be a viable option. The capital expenditures on automation typically have a payback period of at least a year, depending on the volume of production. The higher your desired output and longer program duration, the greater the savings will be compared to using labor alone. A typical example of a cost curve is illustrated below.

- Complexity: The simpler the process you are trying to repeatedly automate, the lower the investment required typically is. This varies by specific industry and application, but a process such as taking durable widgets and packaging them into boxes would be easier to automate than the full assembly and packaging of the said widget. If the process involves more intricate movements such as inspecting each item individually or multiple steps that are dependent on one another—a more intricate solution may be required. Luckily, automation solutions can be implemented in multiple stages. Allowing you to start on one specific part of your production and then continue to add additional subprocesses.

In conclusion, the likelihood that your project is an ideal candidate for industrial automation depends on these three factors. Luckily, as the world of industrial automation continues to advance, integrators such as our team here at Markone Control Systems, are here to help you navigate these complexities. By working with the right team of electrical and mechanical experts—you can be sure that the likelihood of success is maximized no matter your process.