Cobots, also known as collaborative robots, are one of the most interesting recent developments in the robotics and automation space. They promise robotics solutions that are more cost-effective, more accessible, and easier to implement over industrial robots. Instead of replacing human employees, which has typically been the role of conventional industrial robots, Cobots are designed to work alongside humans easily. Many of them can be reprogrammed by simply moving the robot while it is in a learning mode, instead of a robot programmer making all the changes, allowing for greater adaptability.

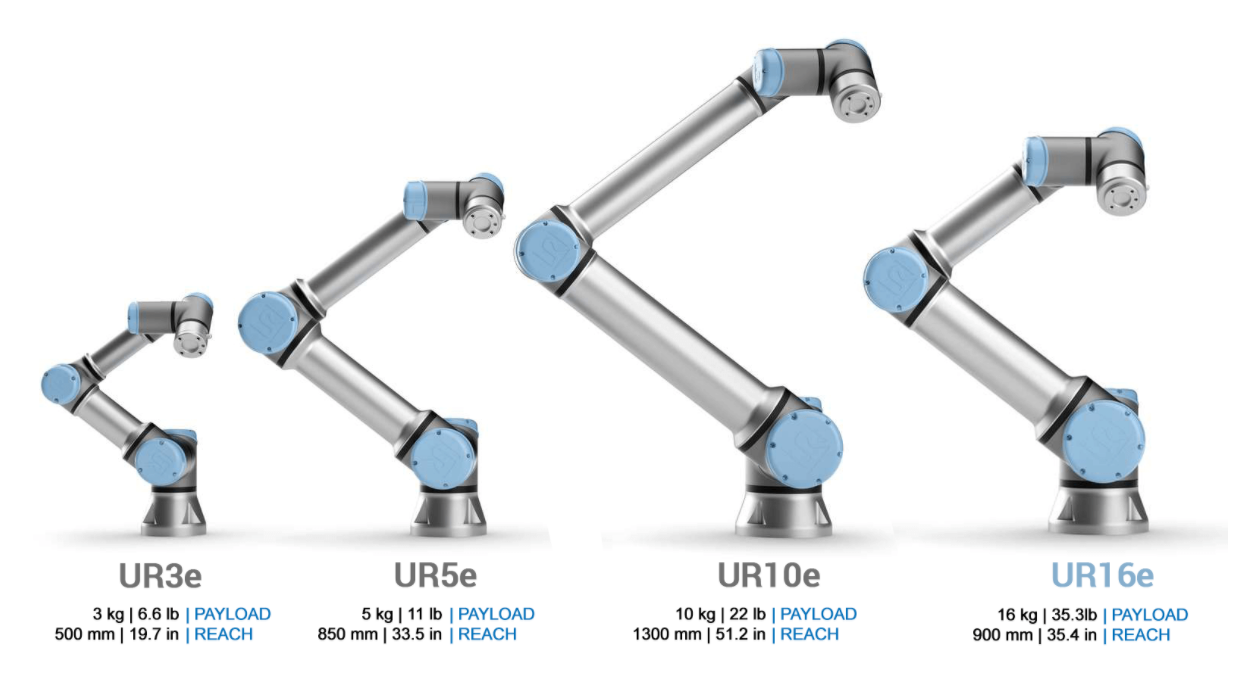

Cobots are often also equipped with technologies like force feedback, low-inertia servomotors, elastic actuators, and collision detection technology allowing for implementation without the need for guarding around each cell. However, conventional industrial robots offer advantages in maximum payload (over 35 LBs) and speed.

If you are looking to automate a process that has a relatively low-volume and high-mix, Cobot-based solutions may be a great fit. One excellent use case for Cobots is CNC machine loading & unloading. Often, these processes are based on small batch sizes with frequent changeovers. A cobot in this use case could be implemented for 20% less than an industrial robot while maintaining comparable performance and allowing for easier part changes when required.

Here at Markone Control Systems, we can provide solutions based on both robot types. Whether your project calls for a conventional industrial robot or a collaborative robot (cobot) our team of experts can help suggest and implement the best option.